plastic impact testing techniques|astm impact tests : suppliers Impact testing is a critical step in ensuring the safety of plastic products. This article explains the importance of impact testing and how to perform it. webBIG COCK JERKS OFF WITH PORN ACTRESS EVA ELFIE SUCKING COCKGLORY HOLE EVA ELFIE 11 MIN PORNHUB. WOWGIRLS EVA ELFIE IMPRESSES THE .

{plog:ftitle_list}

Resultado da 7 horas atrás · Por g1 Ribeirão Preto e Franca 01/03/2024 06h01 Atualizado 01/03/2024 🎉A chegada de março está com muitas atrações para os .

what is impact testing

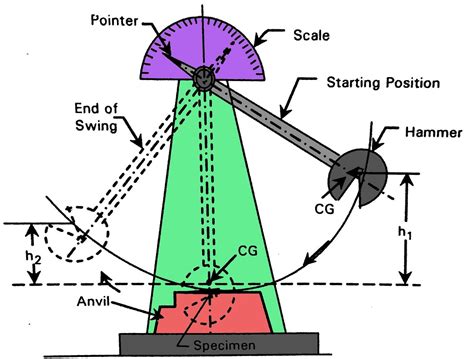

Types of Plastics Impact Testers. The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused .Impact testing is a critical step in ensuring the safety of plastic products. This article explains the importance of impact testing and how to perform it. Laser testing uses helium-neon, diode, Nd: YAG, and excimer lasers to detect surface-level issues. Inspectors first apply stress to the material (e.g., bend it). Then use laser light to create images of surface changes. Laser .

Some charpy testing techniques call for multiple machined bar specimens of 1cm x 1cm x 5.5cm with a 2mm deep U-shaped notch in the middle of a specified flat surface. Another popular impact test is the charpy V-notch notch, which .

Impact damage of a solid laminate generally occurs in the form of a series of delamination . In the NDT of fiber-reinforced composite plastics, structures are routinely inspected using ultrasonic scanning systems and facilities in the .

With the ability to impact test sub size specimens down to 14 sizes, the available impact test specimen types are V-Notch, U-Notch, Key-Hole Notch, Un-notched, and ISO (DIN) V-Notch. Standard single notch and type-X3 specimens can withstand 240 foot-pounds of force during IZOD impact testing. The paper provides dedicated sections on blast and ballistic impact experimentation techniques, covering diverse testing methods for various material classes and configurations used in shielding. It also discusses complex material mechanics during impact response, projectile classifications and characterizations, and the development of .Metals, metallic alloys, or plastic materials can all be used as test specimens for impact testing. The specimen will have a V-shaped notch or a U-shaped notch. If specimens don’t have notches, they may become malformed. . ASTM A370 requirements must be met for a Charpy impact test. A series of techniques for testing steel products are .

Review of conventional and advanced non-destructive testing techniques for detection and characterization of small-scale defects . distortion and warping of the workpieces, due to expansion and contraction of the plastics as they are printed, leads to stress concentration, and the material can also be contaminated with inclusions (e.g .

Testing plays a critical role in the life cycle of a polymer, from the raw material to the compound through to the semi-finished and finished product. Each stage has different test requirements, and each end user may require a different test solution depending on their role, whether it is in Product Development (R&D), Quality Control (QC), Testing Services (TS), or Research (R). Small specimen test techniques (SSTTs), developed for scarce materials, industrial products, in-service equipment, etc., could be challenging to obtain sufficient materials for routine testing. This review focuses on the research on millimeter- and micron-scale SSTTs of metallic materials in the past decade. Mainstream small specimens are divided into similarity, .

Impact testing is a complex and controversial subject, and one that is in the midst of change. . Of the two basic types of plastics impact testers, pendulum types for Izod, Charpy, and tensile impact measure the energy absorbed by the specimen to cause failure. . they include inaccurate or improper notching techniques, as well as subjective . This test is designed to find the amount of mass or volume that flows through the die at specific temperatures in order to determine how the polymer will perform in a number of different processing techniques and to compare batches of material. Impact Testing. There are two types of impact testing, drop tower and pendulum. The drop weight impact testing is highly dynamic in nature and in addition various factors like data acquisition signal noise (disturbance) requires the user to test 3–4 samples for each test . Evolving Manufacturing Techniques: Modern plastic manufacturing is increasingly embracing technologies like 3D printing and nanotechnology, advancing towards more efficient and sustainable production methods. Importance of Sustainability: The plastic industry is actively shifting towards sustainable practices, including the use of recycled materials, biodegradable .

A nanoindentation test evaluates the elastic and plastic properties of materials on the nanoscale by using electromagnetic force and capacitive depth measuring. It is an adaptable method for characterizing a wide range of materials, particularly in a homogenous continuum system. . Two popular techniques for impact testing are as follows.Polymer and Plastic Testing CMH Metlab provides comprehensive polymer and plastic testing services to ensure that your products meet their required performance and safety standards. Our testing services are designed to .

types of impact testing methods

Impact testing is performed to determine the energy absorbed or the energy required to . Plastic 1 4.5 4.427 44.1 0.002 4,517 20,076 . Instron is a well-known leader in advanced material and component testing techniques. They supply instrumentation, support services and expertise for testing materials, products and structures. [2] IZOD Impact Strength Test: Izod impact testing is an ASTM impact standard testing method that can test materials to a ¼ size. It involves using a raised pivoting arm to hit and break material. It involves using a raised . We present pulse shaping techniques to obtain compressive stress-strain data for elastic-plastic materials with a split Hopkinson pressure bar. The conventional split Hopkinson pressure bar apparatus is modified by placing a combination of copper and steel pulse shapers on the impact surface of the incident bar. Different materials testing standards, such as ASTM E23, ASTM A370, and ASTM D256 govern the exact testing procedure and test specimen requirements for each type of impact test, and for different material groups (e.g., metals vs. plastics). While an impact test can help characterize a material’s ability to withstand sudden loads, the impact .

Particularly, PCR testing techniques used huge various plastic inputs, most of which are single-uses for COVID-19 confirmatory test (Tang et al., 2020). . As a result, these plastic residues impact generated from the PCR testing labs during the COVID-19 pandemic, and employing standard management practice is critical.

time, Taylor impact and planar impact specimen can be used for which the load directions even in case of thin plate test material are identical and not perpendicular to each other. Consequences for testing construction elements are discussed. 1. Introduction 1.1. Taylor-test setup Taylor-test investigations can be an important componentMechanical Properties describes techniques for extracting mechanical properties from a wide range of materials, including metals and composites. Small Punch Test describes techniques to obtain mechanical and microstructural data. Two general categories of small punch tests are presented: 1) disk bend tests, where a spherical penetrator deforms .Impact Testing most commonly consists of Charpy and IZOD Specimen configurations. specimen types include V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) . A material's toughness is a factor of its ability to absorb energy during plastic deformation. Brittle materials have low toughness as a result of the small amount of . This study will analyze existing procedures and commercially available testing equipment for low temperature impact testing of plastic materials. The results of this analysis will be used to identify continuous improvement opportunities and develop recommended practices for low temperature impact testing to support ongoing efforts to meet .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .Eddy Current Techniques for Non-destructive Testing of Carbon Fibre Reinforced Plastic (CFRP) A thesis submitted to The University of Manchester for the degree of Doctor of Philosophy in the Faculty of Engineering and Physical Science 2012 Xin Li .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

web83K Followers, 1,598 Following, 2,015 Posts - See Instagram photos and videos from MONIQUE WILBORN | JogadêraFC (@moniquewilborn)

plastic impact testing techniques|astm impact tests